The most widely used waterproofing system is the acrylic base waterproofing system for your toilet and kitchens. SikaSeal®-105 which is a cement based, polymer modified, 2-component, multipurpose waterproofing slurry.

What you will need

- SikaSeal®-105/SikaTop® Seal-107 component A

- SikaSeal®-105/SikaTop® Seal-107 component B

- Mixer 2 paddle

- Wire brush

- Grinding machine

- Block brush / large paint brush

- Bucket to mix

- Water spray

- Gloves

- Mask

- Spatula (small quantities) / mechanical mixer and paddle (quantities exceeding 5l)

Product Information

Step 1

Check surface condition, for concrete it have to define a bleeding surface or un bleeding surface. use grinding machine or still brush to remove loosely adhering particles. make sure the surface is clean, free of oil, grease, dust, or laitance as even possible

Step 2

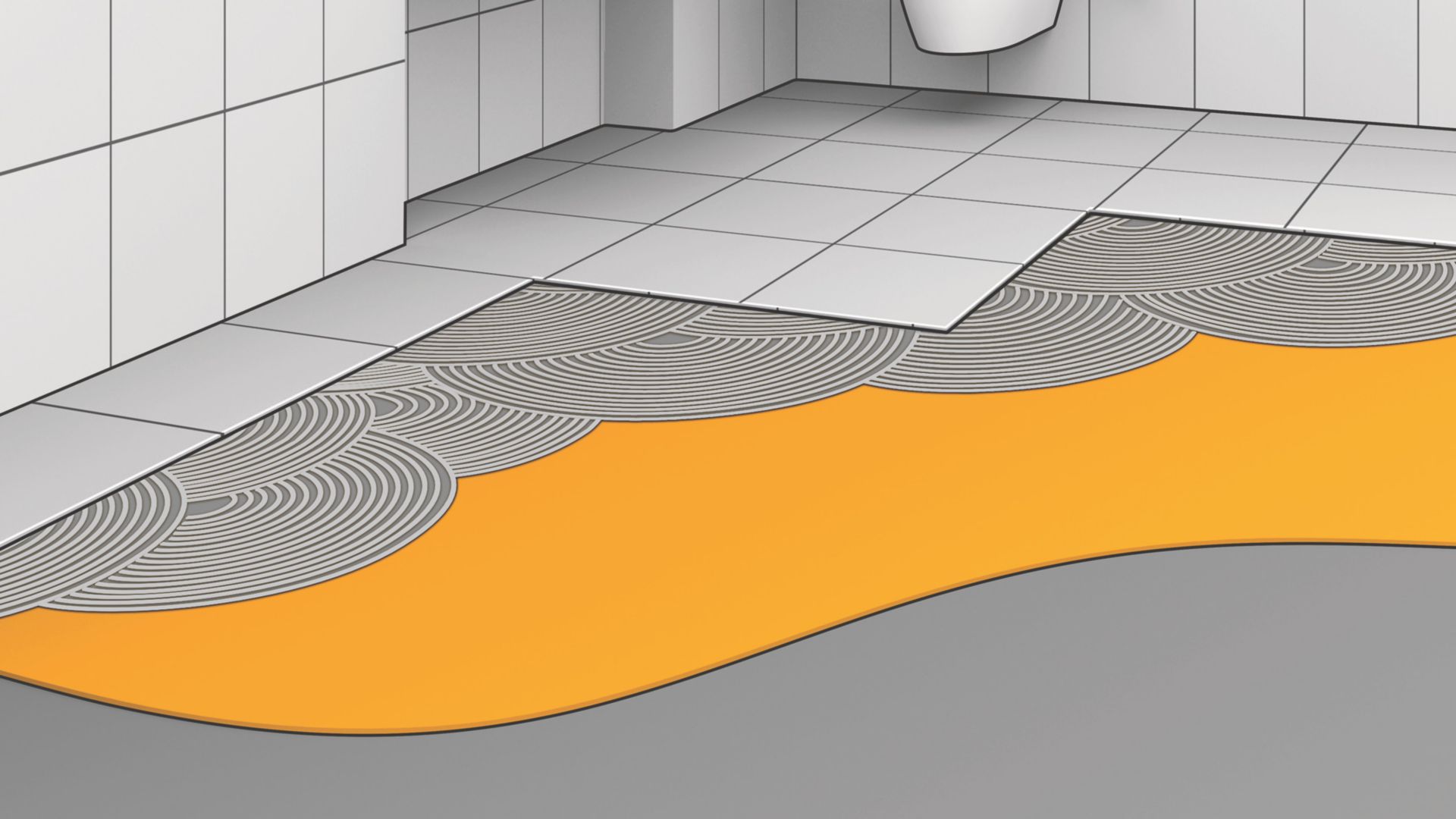

To avoid a cold joint between floor and wall, fully recommended to make a curve (chamfer) using a mortar with SikaLatex®.

The surface should be in saturated surface dry condition prior to the application. Can use water spray or brush with clean water.

Step 3

• Place three quarters (3/4) of component (A) (liquid) in a suitable mixing container.

• Add component (B) (powder) to the liquid while mixing.

• Add the rest of component (A) (1/4) during the addition of the component (B) and

• mechanical mixing (maximum 500 rpm) to achieve the desired consistency.

• Mix for at least 3 minutes, until a homogenous mixture, free from lumps is achieved.

Step 4

Apply the first coat and leave to harden (4-6 hours). After hardening of the first coat, apply the second coat as soon as possible. (Slightly pre-wet the first coat in case of long waiting time). Finish SikaSeal®-105/ SikaTop® Seal-107 by rubbing down with a soft dry sponge.

SikaSeal®-105 should be moist cured for a minimum of 24 hours and then mist cured for an additional 24 hours.

Step 5

Clean all tools and equipment immediately after use with clean water. Hardened material can only be removed mechanically.